Waterworks

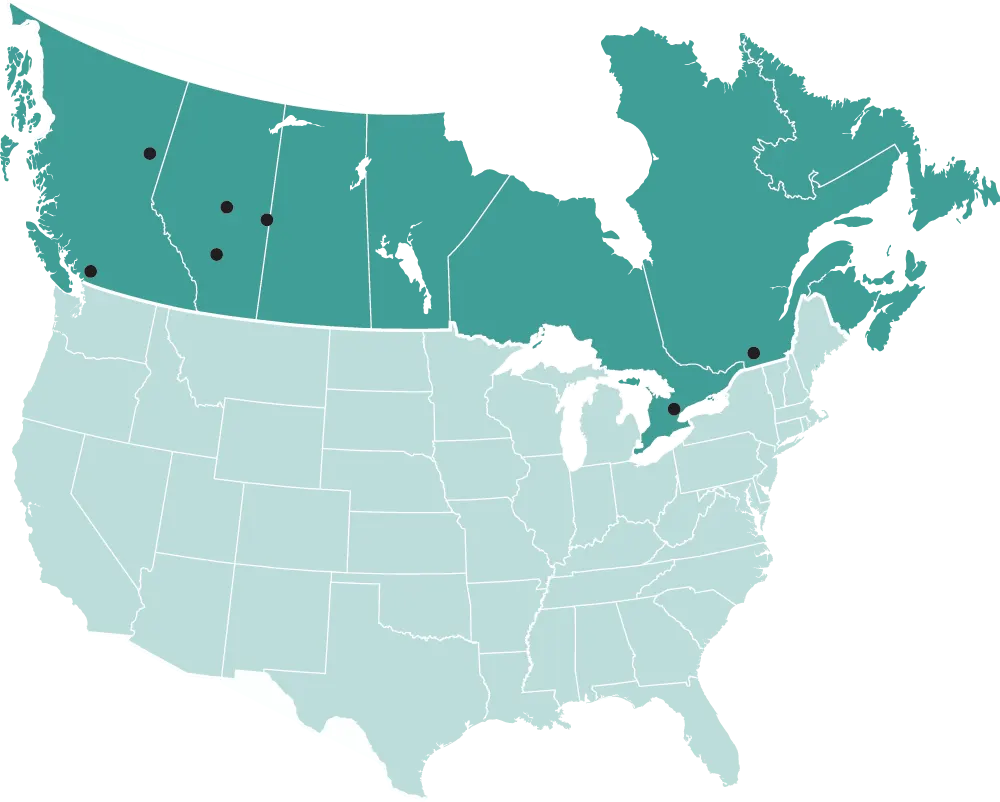

Corrpro Canada™ is a recognized world leader in the field of corrosion monitoring programs, coatings and cathodic protection for both above and below-ground water tanks and well casings. Our National Association of Corrosion Engineers (NACE) have traveled the world helping facility owners implement cost-effective solutions. All of our cathodic protection systems for water tanks are NSF/ANSI Standard 61 certified.

Cathodic Protection for Water Infrastructure

Water Storage Tanks—Subject to Icing Conditions (can also be used on non-icing tanks)

Automatically controlled T.A.S.C.® rectifier with horizontal anode (Permanode®) suspension system

Cathodic protection system components in accordance with AWWA Standard D104 and NACE Standard RP0388

- Available with horizontal or submerged anode Permanode® suspension system

- Titanium mixed metal oxide or platinized niobium impressed current bowl and riser anode assemblies

- Submerged anode support system

- Permanent reference electrodes

- Flotation buoys

- Steel anchors welded to side wall

- Conduit with associated wiring

- Pressure fitting and junction box

- Riser pipes 30-inches in diameter or larger

- 20-year design life

- Annual maintenance program

Galvanic sacrificial anode system

Cathodic protection system components in accordance with AWWA Standard D106 and NACE Standard RP0196

- Magnesium rod anode assemblies

- Submerged anode support system

- Permanent reference electrodes

- Pressure entrance fitting with junction box

- Sacrificial anode test station

- 10-year design life

- Annual maintenance program

Water Storage Tanks—Subject to Non-Icing Conditions

Automatically controlled T.A.S.C.® rectifier with vertical anode suspension system

Cathodic protection system components in accordance with AWWA Standard D104 and NACE Standard RP0388

- Titanium mixed metal oxide or platinized niobium impressed current bowl and riser anode assemblies

- Anode access ports

- Support system bolted to roof for bowl and riser anodes and reference electrodes

- Permanent reference electrodes

- Riser pipes 30-inches in diameter or larger

Galvanic sacrificial anode system

Cathodic protection system components in accordance with AWWA Standard D106 and NACE Standard RP0196

- Magnesium rod anode assemblies

- Anode access ports

- Support system bolted to roof for anodes and reference electrodes

- Permanent reference electrodes

- Sacrificial anode test station

- 10-year design life

- Annual maintenance program

Cathodic Protection for Well Casings

Corrosion on well casings can come in the form of general corrosion or as more localized corrosion in areas where elements such as aquifers, soil conditions or salt caps can accelerate the corrosion rate. Cathodic protection has been used successfully for decades as a means to protect casing strings in production and disposal wells.

Factors such as well depth, casing size, soil corrosivity and electrical continuity must be considered during the design process. Anode systems that are sized or installed incorrectly can degrade rapidly, leading to premature depletion and require replacement in order to adequately manage active corrosion.

Proper protection of well casings can provide years of trouble-free operations and minimize required maintenance. Inspection of the casings is generally expensive, with access for inspection tools often limited by surface equipment and the casing hanger. A purpose-built cathodic protection system prevents corrosion and typically represents one to three percent of the cost of a well. Once installed, ongoing monitoring of the cathodic protection system can be performed without production interruption.

With over 40 years of experience in designing and installing systems that provide long-term protection, Corrpro Canada’s well casing solutions meet both NACE and API guidelines and are very similar to conventional deep anode ground bed (DAGB) systems.

Wells with adequate cathodic protection have far fewer leaks and failures than unprotected wells.